HISTORY:

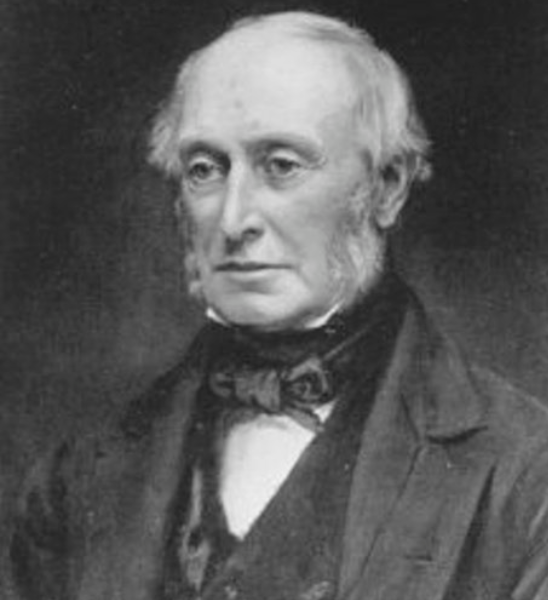

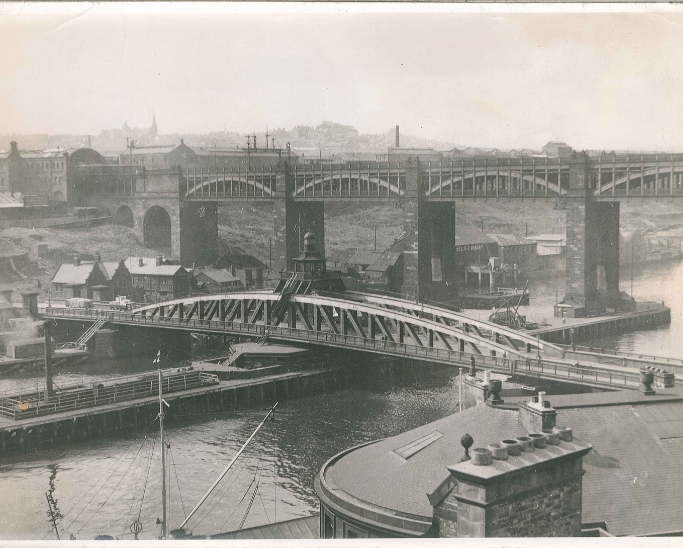

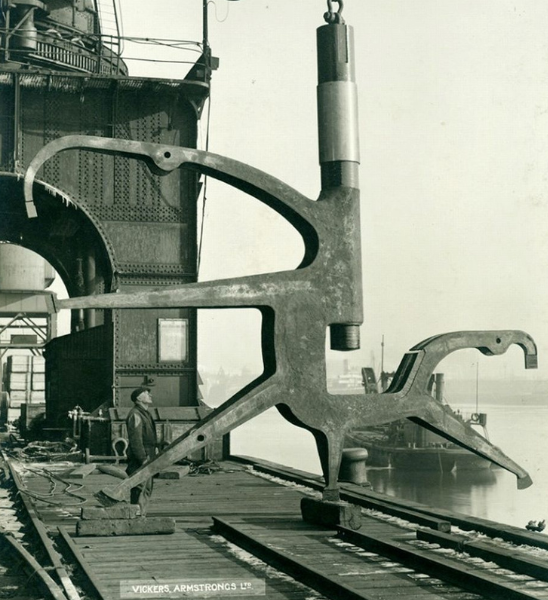

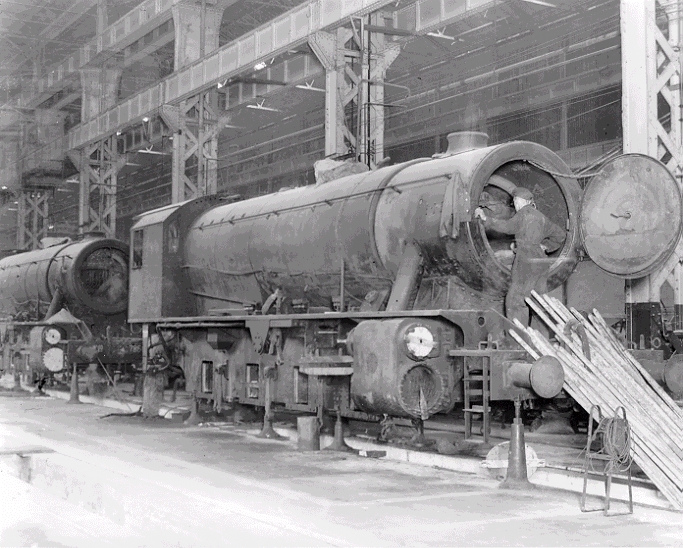

Armstrong Works has an extensive history with significant contribution to engineering thanks to William George Armstrong – not only in the North East of England but also throughout the UK and across the global defence industry. From the mid-1800s to today, the Armstrong Works site has continued to provide engineering, manufacturing and assembly capabilities to major UK defence programmes and armed forces across the world.

Learn more about the key dates of Armstrong Works in the timeline below.

-

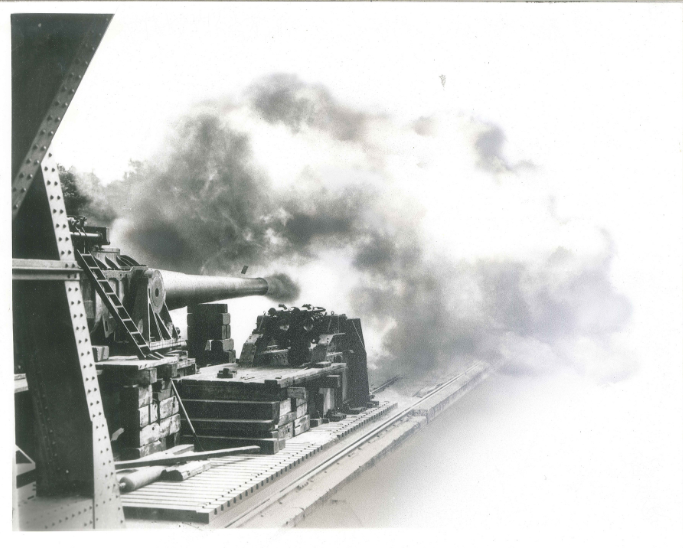

1904

Another Inventor Joins Armstrong-Whitworth

Major Walter Gordon Wilson joined Armstrong-Whitworth to lead the design of motor cars. Walter Wilson was a mechanical engineer and inventor who invented the armoured gun tractor which was acknowledged as one of the earliest armoured fighting vehicles.

-

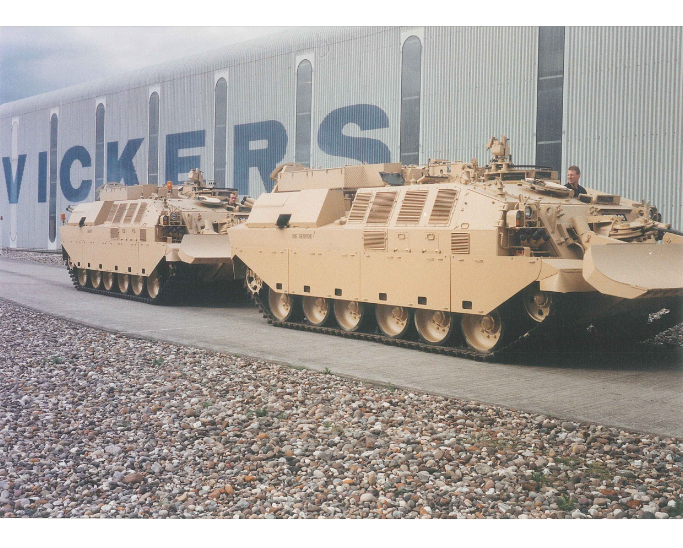

2022

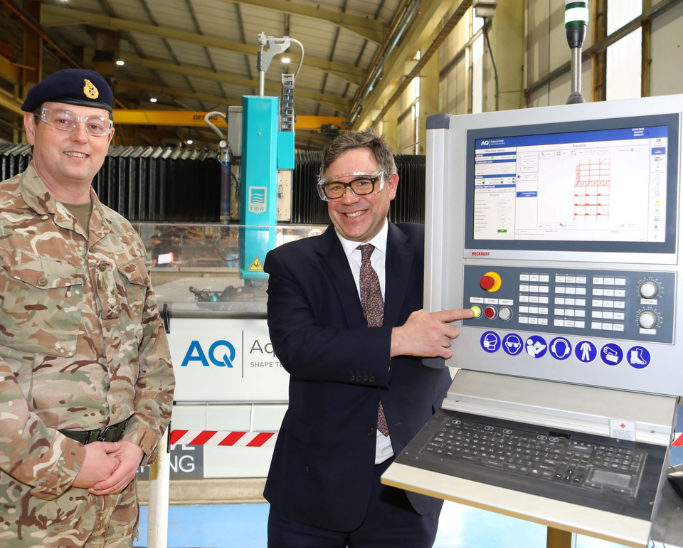

Challenger 3 Supply Chain Production Begins

Challenger 3 supply chain production begins with the first steel cut ceremony for the CR3 turret structures at Armstrong Works. The occasion is marked by Minister for Defence Procurement, Jeremy Quin. Rafael Advanced Defense Systems Ltd, completed the acquisition of Pearson Engineering Ltd.

-

2024

Pearson Engineering Acquires Armstrong Works Building

Pearson Engineering acquired the historic Armstrong Works from its former owners in 2024. The acquisition furthers Pearson Engineering’s commitment to its roots in Newcastle upon Tyne where it has successfully built an internationally recognised brand, serving Armed Forces in more than 35 countries.